The Importance of Inventory Management in Supply Chains

The management of inventory is necessary for any company in order to avoid excess stock storage while at the same time ensuring customer demand is met.

However, customers’ demand can be difficult to forecast due to;

- continuously evolving trends

- variability in customer preferences

- the need to maintain a sufficient supply of materials and goods to buffer variability.

The optimal balance, however, is often achieved through properly planned and managed inventory.

Sales and Operations (S&OP) Process

To help reach the balance between planned and actual, many businesses implement the S&OP process. The basic purpose of S&OP is to bring the demand management functions of a company, for example, sales forecasting and marketing, together with the operations functions (i.e., manufacturing, logistics, and procurement) to level the strategic plans.

This process regularly includes extensive modeling and discussions about the company’s on-hand, in-transit, and work-in-process inventory. This way sales and marketing teams can effectively plan for the period, by obtaining a realistic picture of the inventory levels available for sale. At the same time, the operations teams are updated with direct sales forecasting information, which can contribute to planning for near-term and future inventory and manufacturing needs. This information can drive a shift in manufacturing plans or procurement needs because of an S&OP decision to focus on specific products requiring additional inventory.

Point-of-sale (POS) Data

Another way to achieve the balance is through POS data for inventory management in the retail industry. Every time a barcode is scanned during checkout it captures data. The information is not only tracked by the retailer but is often distributed to upstream vendors. As items are removed from inventory, in some cases, both the retailer and vendor collaborate together to determine when reordering is needed. Demand information is tracked to determine when the best time to place replenishment orders based on the lead time required and variability present when moving the inventory to a downstream location.

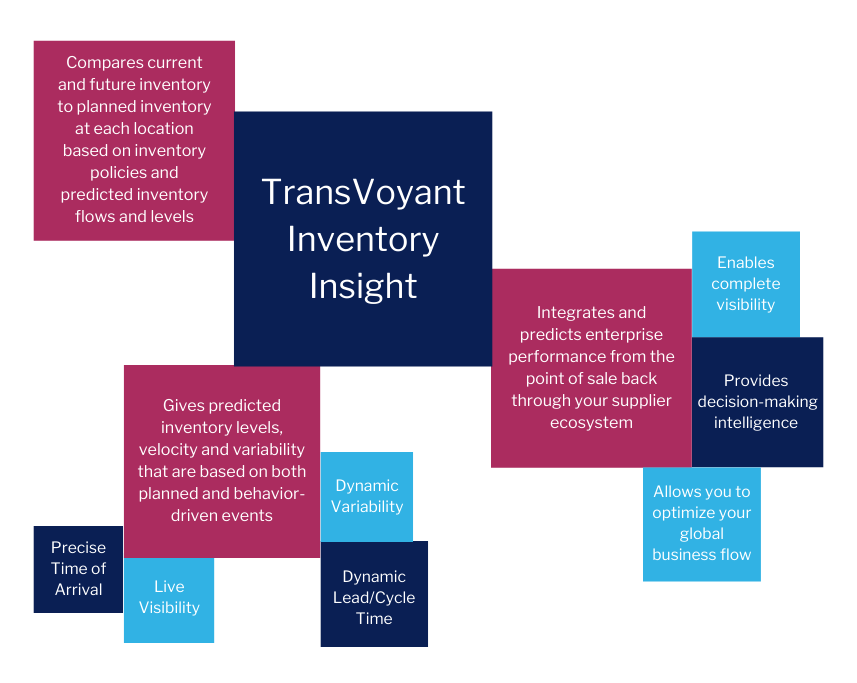

TransVoyant Inventory Insight monitors the behavior of on-hand inventory at your and your trading partner nodes, including raw materials, work-in-process, and finished goods as well as in-transit inventory planned to flow in and out of nodes.

What you gain from this insight is not only visibility but;

- the understanding of the behavior of on-hand and projected inventory across your entire network and ecosystem

- knowledge of your business exposure to inventory disruptions in a lane or in a node

- the ability to identify trends between inventory and other metrics, such as service levels and supplier performance.

If this information sounds intriguing, please click here to speak with one of our experts regarding your inventory management needs.