Live Supply Chain Situational Awareness: Temperature Controlled Logistics

The environment in which life sciences companies operate is increasingly complex, being driven by a more and more demanding healthcare agenda. The global need for innovative, cost-effective medicines continues to rise. At the same time, patients are demanding greater value for money, proven effectiveness of products, and access to information. To meet these demands, companies are seeking ways to improve their operations efficiency.

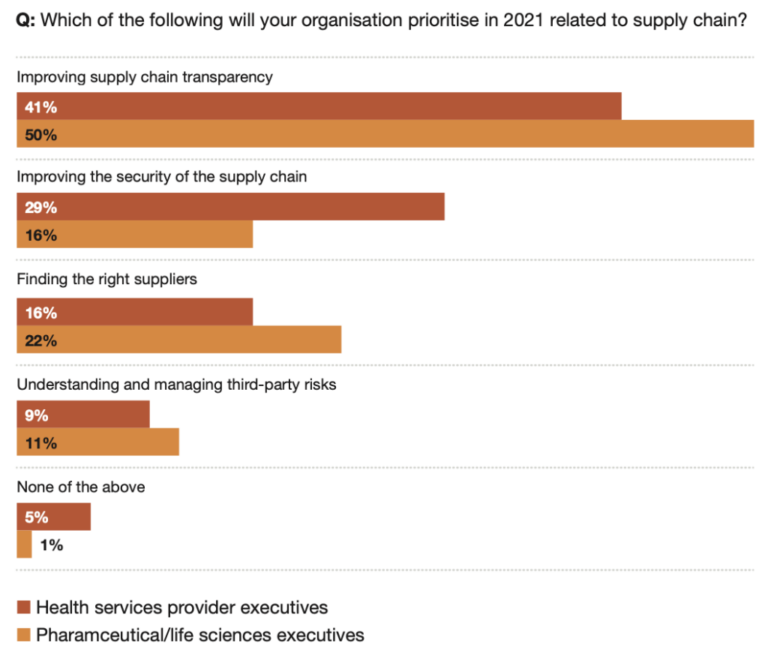

Nearly 60% of respondents in the Pharma Logistics IQ-TransVoyant survey invest in end-to-end visibility and almost 40% have fully operational solutions.

However, this contrasts with other survey responses, where respondents cited challenges such as a lack of willingness to spend money;

- 39% said budget constraints were the main challenge

- 25% faced obstacles in building a business case.

As illustrated above, investment in end-to-end visibility often tends to be low, making achieving true supply chain transparency challenging.

Adding to the complexity are the risks inherent with cold chain shipping and the security of medicines while in transit. Such parcels require 24/7 monitoring to ensure patients’ safety and product quality.

Solution

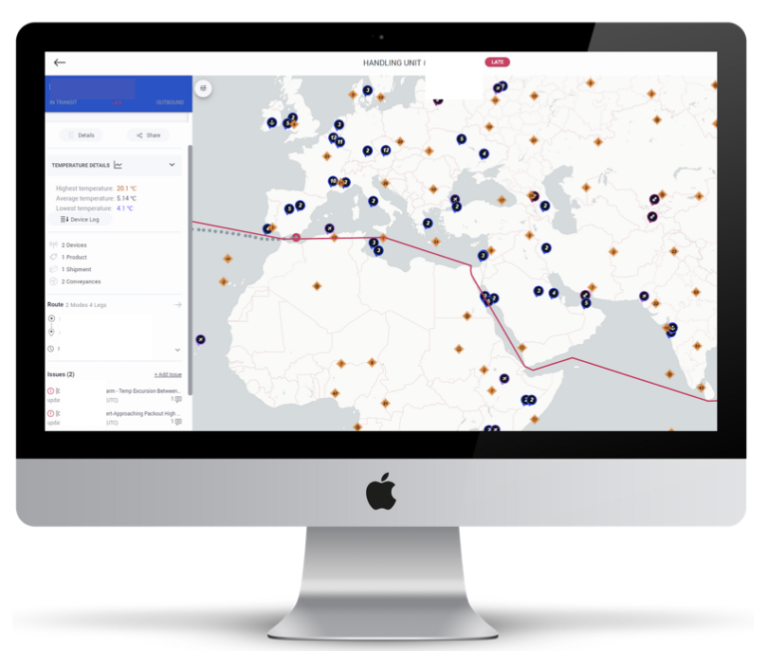

Digitizing Temperature Controlled Logistics (TCL) can provide supply chain leaders with a Common Operating Picture of the life and condition of all customer orders. This enables internal teams to understand time delays, product condition and external events. The result is continuous improvement of patient safety, logistics planning and execution and discards elimination.

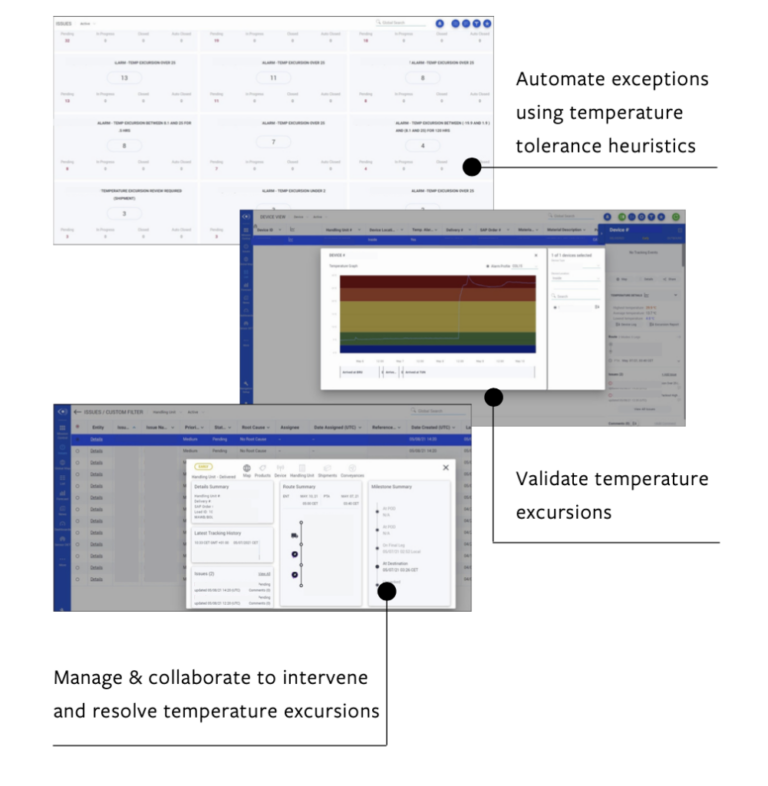

Leveraging TCL capabilities, one global Pharmaceutical company conducted enough shipments interventions to prevent over 1 million discards of medicine doses by reacting and responding in real-time to temperature excursions. Their team was able to develop a TCL solution for global delivery and quality business divisions via automation, exception management, analytics and reporting.

Key program features included:

- automated reporting of SOP compliance and adherence to carrier, lane, route and thermo-packaging units

- seamless end-to-end connection of order, shipment, IoT, carrier, mode and external event information

- Machine Learning powered predictive insight and automation providing daily operational intelligence.

By leveraging these tools, pharmaceutical companies can transform and automate their entire shipment intervention process, benefiting quality and audit team workloads, reducing manual reporting claims and lowering insurance premiums.