What Is a Supply Chain Control Tower?

By TransVoyant Team

If you ask ten different executives to define a supply chain control tower, you will probably get ten different answers. Most of them will involve some sort of oversight and orchestration of supply chain logistics, but they won’t all agree on the full extent of the orchestration that a supply chain tower enables. They rarely dive into the potential that a supply chain control tower can not only identify, but actually foresee and prevent issues from occurring.

In other words, supply chain control towers are capable of much more than we give them credit for. Let’s dig a little deeper into the hype and common misinterpretations around the term.

A Supply Chain Control Tower Starts with Visibility

The word “tower” means more than we may realize.

It evokes images of an airport control tower, standing high above the planes, baggage carts, and ground-based personnel. Someone standing in a control tower has full visibility of all these parts so they can effectively orchestrate their movements and ensure safety. The complex visibility and orchestration are laser-focused on satisfying demand to safely move people and freight on time and in full.

Visibility, of course, is a big part of digital supply chain solutions. But when most people talk about supply chain visibility, they naturally think about goods in motion. Unfortunately, this is where the misconceptions begin.

Having visibility to goods in motion is a strong starting point but is of limited value without a continuous understanding of end-to-end supply chain behavior.

Figure 1: Supply chain control towers provide omniscient oversight so that managers can calibrate and respond to varied disruptions appropriately.

A controller standing in an airport tower, having full visibility of all the moving parts beneath them and around them, is analogous to a supply chain professional standing in a war room and staring up at a Common Operating Picture (COP) that shows all goods in motion, assets in nodes, and the dynamic events surrounding the interconnected supply chain.

The COP is certainly a part of a digital supply chain solution, but that is the jumping-off point for a better definition of a supply chain control tower.

What is the point of far-reaching and real-time situational awareness if it doesn’t drive better outcomes and if it doesn’t result in greater early behavior warning and control?

Controlling the Supply Chain Control Tower

Let’s now look more closely at the word “control.”

Control in the phrase “supply chain control tower” is about learning, understanding, predicting, and improving the behavior of things, nodes, lanes, routes, and people in a global supply chain. This is also a primary value driver in a truly digital supply chain.

Today, this power is made possible by artificial intelligence (AI). Sophisticated AI computer models can create a real-time picture of supply chains, including suppliers, inventory in motion, ports, carriers, roads, manufacturing facilities, warehouses, static inventory, customers, stores, and even employees. They can see external risks such as natural disasters, severe weather, labor strikes, socio-political trends, consumer sentiment, and civil unrest, as they unfold in real time. The more data it ingests, the better AI learns and understands continuously changing networks of supply chain nodes, lanes, routes, operations and the interdependencies and behaviors associated with every actor and every activity from n-tier supplier to end customer.

These insights enable organizations to predict future risks by always understanding patterns of life behavior, behavioral anomalies, and the correlated independent variables that serve as leading indicators of future behavior.

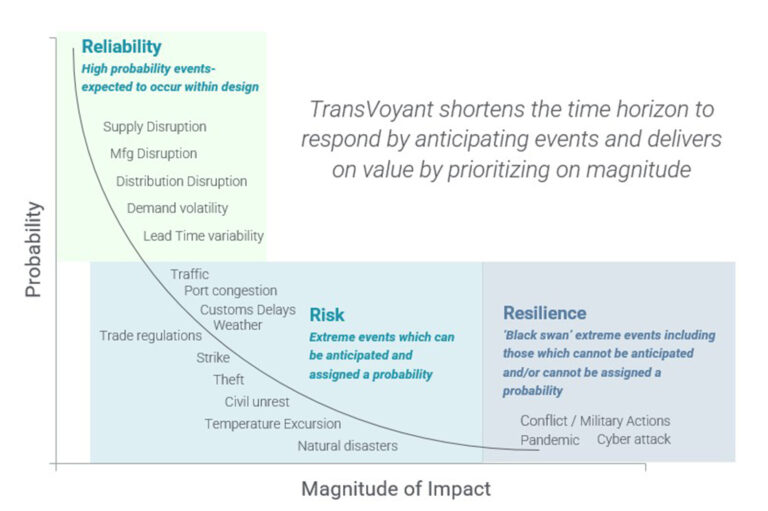

Predicting and assessing future risks reveals game-changing details, including how likely disruption is to develop and how much impact it will have. And prescriptive insights based on AI models point managers in the best direction for controlling outcomes.

Today’s definitions of a control tower remain limited, and supply chain managers must go beyond mere visibility. True supply chain control requires real-time, connected, predictive, and prescriptive global supply chain situational awareness.