5 Best Practices for Preventing Port Logistics Risk

By TransVoyant Team

Strike actions are on the rise, and nowhere is this more evident than in port operations. Workers involved in work stoppages increased by 280% in 2023, according to the Economic Policy Institute, and this statistic is particularly disruptive at the world’s ports. While ports are a more affordable and sustainable mode for moving global goods than air freight, port reliability is increasingly unstable. Are the lower rates worth the high chance of disruption? It is, but only if you have the right management tools.

According to Reuters Events research, 40% of companies say their supply chains failed them at the height of the pandemic. “Failure” meant lost revenue, dissatisfied customers, and increased cost-to-serve. Due to those failures, 80% of companies say they accelerated their digital supply chain strategies to protect revenue and improve customer satisfaction.

Furthermore, almost 50% are looking to overhaul procurement and risk management strategies within the next two years, and 42% of enterprises are now using automation to manage risks.

To gain full transparency for managing a digital supply chain, including port conditions, managers need to have situational awareness of the following inhibiting factors:

- Variance in actual versus estimated arrival times

- Latency in EDI data used by global trade networks

- Inefficiencies in the systems used to store and move containers

- Congested roads and choke points in and around port terminals

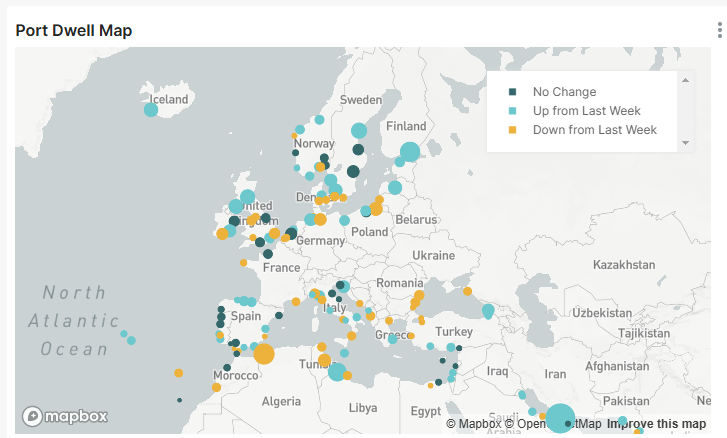

After the COVID pandemic, Suez and Panama Canal blockages, and ongoing labor strikes, many supply chain leaders focused on the ports that their goods flow through for opportunities to improve performance. Port-related supply chain disruptions cannot be eliminated entirely, but with new capabilities enabled by the Internet of Things (IoT), predictive analytics, and machine learning, those risks can be significantly reduced.

Innovators who take advantage of digital supply chain platforms can gain a competitive advantage, obtain real-time transparency for shipments and orders, and leverage predictive insights that enable them to avoid or mitigate port-related disruptions.

TransVoyant recommends the following five data management best practices to avoid or minimize port-related supply chain disruptions.

1. IoT and Other Real-Time Data for Port Logistics

Don’t rely on EDI data, with its latency problems. Instead, utilize IoT, sensors, and other real-time data sources to get the most accurate picture of live and predicted port performance. The more data sources your digital supply chain ecosystem can ingest, the more valuable insights it can reveal.

A truly device-agnostic platform will be able to onboard and manage any data flow from any device and integrate it into your digital twin. The best can also source the data they need to fill gaps.

2. Predictive Risk Analytics for Port Logistics

Utilize predictive analytics to get alerts on global risks prioritized by revenue and/or inventory impact. Foresee disruptions and events before they occur and, therefore, gain advance notice of events in time to take preventative or remedial action.

The payoff comes in preventing disruption, protecting revenue, and maintaining customer service.

3. Emissions Tracking for Port Logistics

Compliance increasingly demands that companies not only track and report their supply chain emissions but also lower them. These requirements increasingly apply to the entire supply chain.

Emissions tracking combined with accurate predicted arrival times can support companies in shifting from air to ocean, lowering carbon footprints and saving on shipping costs.

4. Diagnostics Insights for Port Logistics

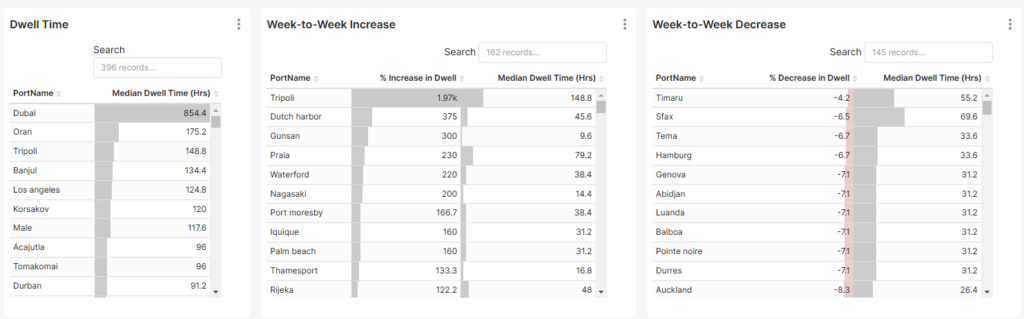

Use an analytics solution to gain strategic and diagnostic insights into the performance of ports, carriers, routes, and suppliers.

Predictive ETAs can be used to compare to shipper data, or inform more accurate for planning buffer stock.

5. End-to-End Multi-Modal Management for Port Logistics

Rather than using a collection of single-mode solutions, use and end-to-end multi-modal solution that provides real-time visibility and predictions related to both the inbound ocean shipment as well as the outbound truck or rail movement in a single system via a single dashboard.

Traditional supply chain and transportation management solutions have not been successful in addressing highly volatile port-related issues, but IoT and predictive analytics-based technologies are changing the game.